- Product category

- Rubber vulcanization insulation works.

- Flexible removable soft insulated industrial system.

- Plastic insulation energy saving series

- Extruder insulation energy saving series.

- Pipe insulation cover

- Removable insulation cover.

- Nanometer infrared energy-saving heating coil

- Energy-saving heat preservation cover for dryer

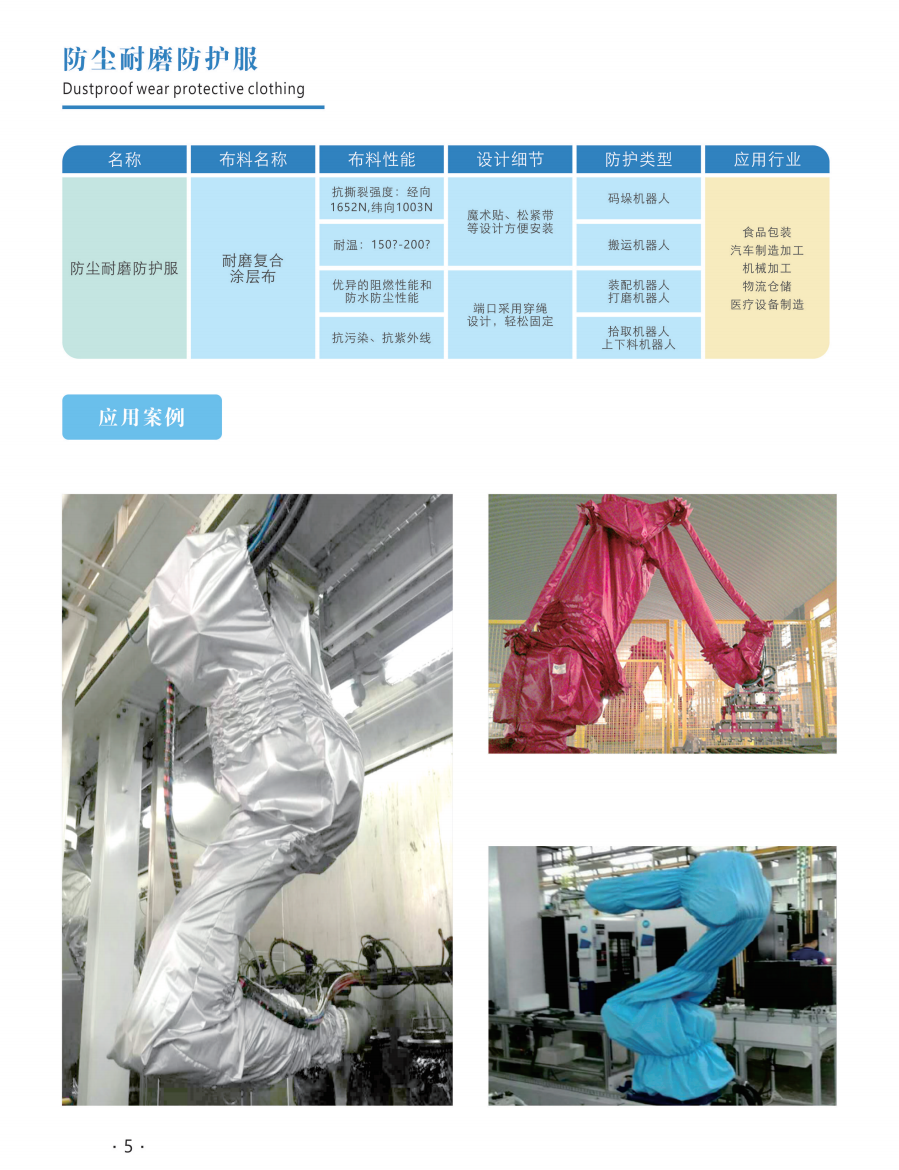

10/5000 Dustproof and wear-resistant robot protective suit

Sort:

Model:

Prices:¥1

Update:2012-9-17 10:36:27

View: 0次

Feedback:To Message

Keywords: antistatic robot protective clothing, dustproof and wear-resistant robot protective clothing, welding clamp robot protective clothing,

Cleaning robot protective clothing, window type robot protective eye, heating and insulation robot protective clothing

Yiyuan specializes in providing automation system protection solutions, creating its own brand "Yiyuan Protection" we provide personalized protection solutions according to different production systems, production environments and protection needs. Products and services involved in automobile manufacturing, casting, forging, food and medicine, rubber and plastic industries. The company has a highly professional technical team, has been adhering to the "product first, service first" concept, dedicated to provide our customers with professional, honest, intimate, thoughtful products and services. After years of efforts, the company has established good cooperative relations for Chery, Haima, Wuling Automobile, Great Wall Motor Group, Dongfeng Yulon Natzhijie and so on, and gradually become a well-known enterprise widely recognized in the industry.

Scope of application:

Yiyuan specializes in the production of customized robot protective clothing of various specifications, dustproof and wear-resistant. Suitable robot protective equipment can be customized according to the actual function of the robot. Good protective effect and long service life, welcome to learn more about protective equipment information! Robot protective equipment _ protective clothing in the design and production, are tailored according to the actual needs of the robot, beautiful appearance and reasonable overall design, easy to install and disassemble, the protective effect is very good, can effectively protect the safe production of the robot.